Mobility and independence are very important. The Triton family of feet are designed for highly active users; a selection of prosthetic feet are available that are reliable in any situation. Mobility at the highest level, for enhanced quality of life.

As diverse as the Triton family is, all of the products feature the innovative triangular spring system. This design is modelled after the human foot. The result is an especially natural, harmonious gait pattern. From heel strike to the stance phase to pushing off for the next step.

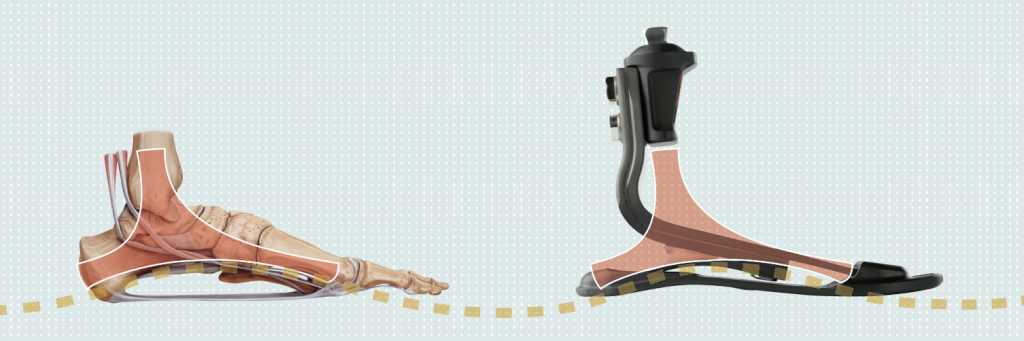

The Human Foot

In the human foot, the flexible forefoot structure is connected to the supporting heel via the plantar fascia (aponeurosis). The interplay between the different muscles and tendons thus controls the movement of the foot. When you put weight on your heel, during rollover or when pushing off with your toes, there is a harmonious flow of force throughout your entire foot unit.

The Triton Foot

The anatomy of the natural foot is reflected in the characteris- tic, curved, triangular form of the Triton prosthetic feet. They are comprised of three interconnected spring elements. A car- bon forefoot spring and a two-part carbon heel spring form the load-bearing structure. The high-performance polymer base spring in turn connects these elements to form an integrated unit and provide for a particularly smooth rollover.

• Pyramid Adapter made of lightweight aluminum or titanium

• Carbon Forefoot Spring - The split forefoot spring allows the foot to adapt to uneven surfaces. It offers high energy return, stability and control at rollover and toe-off

• Base Spring - The high-performance polyester split base spring has a separate big toe, and connects the forefoot and the heel spring to form a complete unit

• Carbon Attachment Spring - The attachment spring made of carbon fibre material gives the foot the required stability

• Carbon Heel Spring - The heel spring dampens the impact at heel strike and stores the energy for a smooth rollover

• Replaceable Heel Wedge - The optional heel wedges provide a simple method for adapting the Triton to the individual needs of the patient

Triton 1C60

The full size Triton 1C60 foot provides the most energy return, but the overall build height may limit its usability in some situations.

Triton 1C63

The Low-Profile Triton 1C63 foot combines the outstanding dynamic response and flexibility of the Triton with a considerably reduced structural height. The titanium adapter makes the foot extremely resilient as well as water-resistant.

Triton 1C64

The Triton HD (Heavy Duty) 1C64 version offers a higher load limit for highly active users and is also water-resistant. The foot is recommended for particularly challenging conditions - at work or play.

Advanced GENIUM X4 Microprocessor Knee

The Genium X4 microprocessor knee is the most advanced knee from manufacturer Ottobock. Building on the revolutionary Genium and Genium X3 knees, the Genium X4 is durable and perfect for rugged conditions; taking function and mobility to a new level. Many new enhancements and upgrades make the Genium X4 the most efficient hydraulic microprocessor knee available!

In 2020, Ottobock reached out to our clinical experts at Dream Team Prosthetics to collaborate with their R&D design engineers on the development of the Genium X4 knee system! Dream Team Prosthetics was one of two companies in the world involved in the multi-year Genium X4 clinical study and the only clinic to involve bilateral above knee users! The Genium X4 was finalized and released to the world in the spring of 2024!

Genium X4 Features:

• OPG 3.0: Optimized Physological Gait is built into the DNA of the Genium X4, providing exceptionally smooth and natural walking characteristics, PreFlex shock absorption, adaptive yielding, stance extension and adaptive swing phase control

• Optimized Slope Ascent: greatly reduces stress and energy expenditure when walking up slopes by keeping the knee slightly bent to match the angle of the slope

• Start-to-Walk feature: the knee naturally releases and bends on the first step after standing; useful when standing and taking short steps while waiting in line

• Enhanced Stance Phase Support: stance phase yielding intuitively adjusts over a wide range from flat level to slight to very steep slopes, providing consistent yielding support no matter the angle

• Dynamic Backward Movement: provides high resistance to push against when taking large, backward steps and even allowing for pulling heavy objects

• Smartphone Connectivity: Cockpit app compatible with iOS and Android devices

• MyModes: Numerous new, preconfigured modes and an extensive range of new adjustment options are available for even more individuality and customization

• Enhanced Stumble Recovery: sampling input from the knee sensor array to identify interruption in the gait cycle to provide instant yielding resistance

• Supported Stance Yielding: by increasing yielding resistance as the knee angle increases provides a new level of support when walking down ramps or sitting

• Stance Lock Function: two different stance functions are selectable by the clinician, that permit resting on the prosthesis side; a supported lock even when bent

• Five Day Battery: five days of normal use from the integrated lithium ion battery; the knee provides preset yielding resistance "safe" mode when battery is completely drained

• IP68 Rating: Electronic components are protected from 3 meter water submersion; corrosive-resistant when exposed to chlorinated or salt water environments

• Walk To Run: The walk-to-run function lets you change speeds spontaneously for short sprints when necessary

Ottobock C-Leg 4 Plus

Advancements in prosthetic technology have greatly accelerated since the introduction of microprocessor control systems incorporated into prosthetic components. The original Ottobock C-Leg was introduced in the United States in 1998, offering the first microprocessor regulated hydraulic swing and stance phase yielding during the gate cycle. The consistent response and stability of computer regulated hydraulics opened up the possibility of using prosthetic limbs to people that previously were unable to successfully utilize an artificial limb. This revolutionary technology was enhanced when they added the ability to program specific activity modes for the user to select with the Cockpit control app.

An underserved patient population that this technology can greatly impact are individuals with bilateral above knee limb loss. Without having a "good" leg to catch them if they stumble, microprocessor control of the hydraulic actuator, updated 100 times per second while walking, provides the consistent stability and support necessary. The C-Leg revolutionized the industry and continues to be the benchmark for prosthetic knee systems.

The latest iteration is the C-Leg 4 Plus, utilizes a gyroscope and other sensors to control the electronic servo valves of the hydraulic cylinder. Using a hydraulic actuator, this knee mimics the natural movements of the human knee and provides consistent, smooth function to the prosthetic user. The knee features natural "stance flexion" with each step to help promote a more natural gait and ease of activation of the yielding of the knee when walking down ramps, stairs or stepping off of curbs.

The new C-Leg Plus further expands capabilities by offering "supported yielding" when walking down ramps and stairs. There are now selectable "stance lock" behaviors that can be selected by the prosthetist at the time of programming. Ottobock continues to improve and enhance the function of this incredible technology.