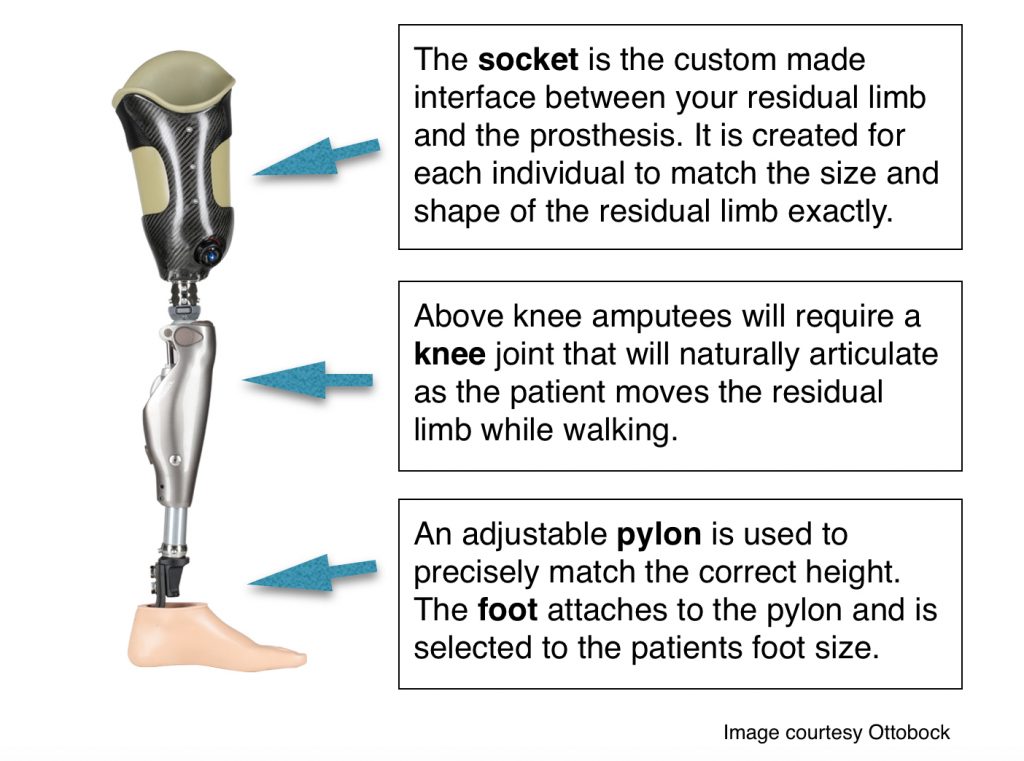

A prosthesis is made up of many different components. The most important component of every prosthesis is the custom fit socket. The socket is the crucial interface that is the foundation for connecting the prosthesis directly with your residual limb.

Creating the socket requires a high level of clinical expertise to insure a secure fit. The shape of your limb is captured by wrapping it in plaster to create an exact mold of every detail of your limb. The cast will then be used to make a positive replica of your limb. This mold will be the basis for creating the completed socket system.

The inner socket is usually fabricated from a soft and pliable bio-elastic material that will respond to your residual limb muscle movements. The outer supportive frame is constructed of advance carbon composite material, similar to what is used in the aerospace industry. The carbon composite frame is very lightweight and yet retains strength for the areas that need to have firm support.

At Dream Team Prosthetics, we have dedicated our clinical expertise to developing a unique socket interface that will provide excellent control and reduce discomfort as much as possible. Our custom socket design and fitting techniques are the optimal combination for the most successful outcome for our patients.

The goal for every socket is to fit the remaining limb as accurately and uniformly as possible. This is the most critical aspect of maintaining a high level of function with the prosthesis as you incorporate it into your daily activities.

For the prosthetic user, this means they will have a socket that is form fit to the unique shape of the residual limb, providing protection, comfort and control of the prosthesis. All amputation levels can benefit from our advanced, customized socket fitting approach.